Meaning of Rotary Valve in Music

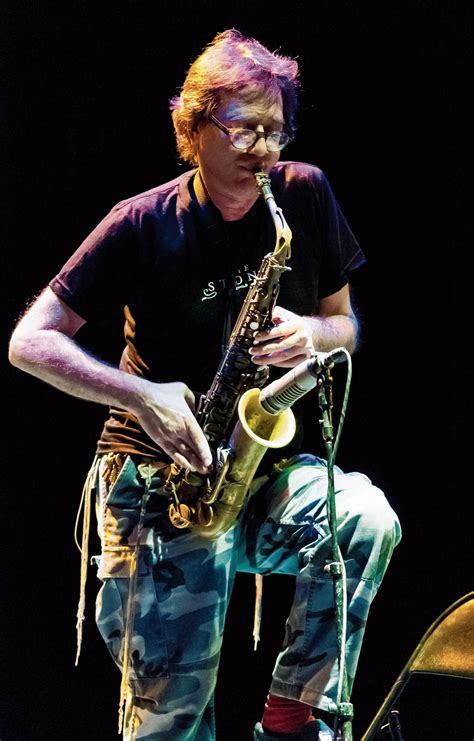

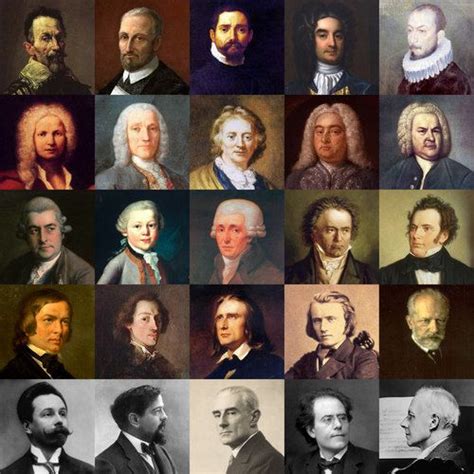

In the context of music, a **rotary valve** is a type of valve mechanism used in certain brass instruments, such as horns, trumpets, trombones, flugelhorns, and tubas.

Unlike piston valves, which work vertically by pressing down on a button, rotary valves operate by turning a circular rotor using a lever. This rotation opens channels that allow air to flow into additional tubing, thereby changing the pitch of the instrument.

Rotary valves are known for providing a smoother and more continuous airflow, which can result in a more seamless and fluid sound compared to piston valves. However, piston valves are generally considered to be more precise.

It's worth noting that different brass instruments may have different valve configurations. For example, the trumpet can have either piston valves or rotary valves, depending on the design and style of the instrument. Similarly, tubas can have three to six valves, with some models featuring rotary valves and others featuring piston valves.

The choice between rotary valves and piston valves in brass instruments often comes down to personal preference and the specific requirements of the player and the musical genre they are performing in. Both types of valves have their own unique characteristics and advantages, and musicians may choose one over the other based on factors such as sound quality, playing technique, and musical style.

Overall, rotary valves play a crucial role in brass instruments by allowing musicians to change the pitch and produce different notes with precision and control.

See also valve, piston valve.

Leave a Reply